Synopsis

What’s Recycled Film Faced Plywood

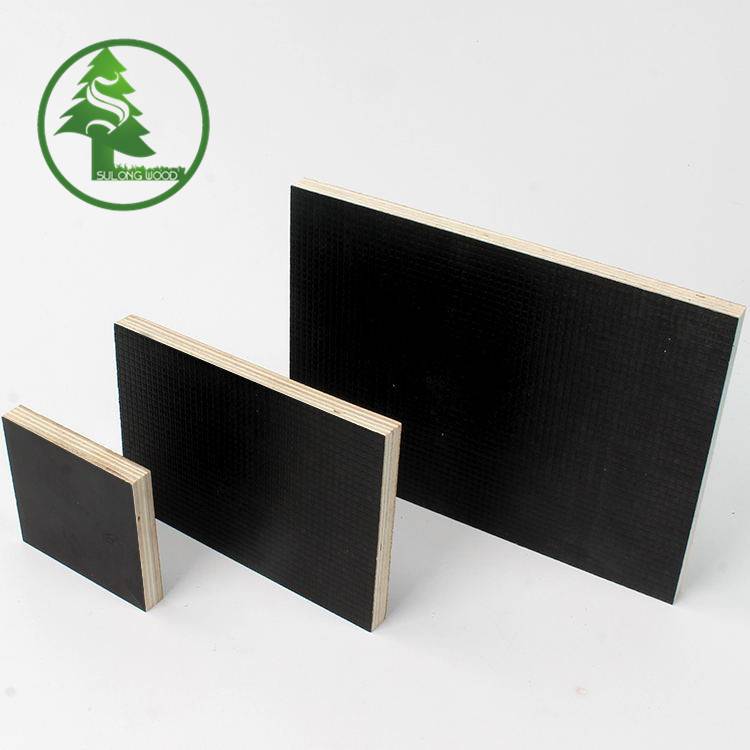

Recycled Film Faced Plywoo uses processed 2nd hand plywood as middle core and applies fresh veneer layers on top and bottom of recycled middle core to be pressed into 1 new sheet of plywood. it was created by Chinese plywood producers about 8 years ago to meet global buyers’s demand:

1). Very Cheap Price

2). 1 time use and throw away(especially in Europe)

3). Saving wood and protecting the environment

Customers can get 12mmFinger joint recyclable FJ core film faced plywood from us. The finger-joined combination recyclable FJ core film facing plywood we provide is widely praised for its excellent performance and is suitable for various construction applications. The laminated plywood we provide is coated with a high-quality film to ensure its hardness and resistance to destruction. Customers can use recycled FJ core film plywood with finger joint combination from us at market leading prices.

Examining Report

| Name | Concrete Formwork /Formwork Plywood |

| Core | poplar,eucalyptus,pine,birch,hardwood,combi |

| Face/Black | Brown,Black,Red,Green film |

| Size | 1250*2500 or 1220*2400 or 1500*3000mm |

| Thickness | 3-30mm |

| WBP(WBP-boiled for 48hours,reused times 15-20/MELAMINE-boiled for 6-8hours,reused times 8-12/MR-boiled for one hour,reused times 6-8)Amount of the glue,take 1.7mm thickness veneer for example,the amount of glue used in other factory is 0.25kg/m2, and our use is 0.33kg/m2,it will ensure the high strength of plywood in application. | |

| Glue | |

| Formaldehyde release | E1≤1.5mg/L E2≤5.0mg/L |

| one time hot pressed,two time hot pressed,(difference: two time hot pressed plywood smooth surface;one time hot press,low cost and cheap price.Choose by your market) | |

| Hot press | |

| Cycle life | 6-20 times |

| Logo | customized logo by customers |

| Density | 530-700kg/cbm( poplar-530kg/m3, combi.pine-635kg/m3, hardwood-660kg/m3,birch-700kg/m3) |

| Grades | AA |

| Moisture | <=12% |

| Packing | Standard exporting package( bottom is pallet, covered with plastic film, around is carton, strengthen by steel tape with 3*6 |

| MOQ | 1*20'GP |

Inquiry Now

You Might Also Like